Introduction

The SRIZFLY UAV simulator is used for UAV oil and gas inspection training and provides a comprehensive and realistic training environment. The simulator uses advanced technology to accurately replicate the performance and control of the UAV under various conditions. In addition, the system can also support training mode and assessment mode; the training mode supports step list display, UAV crash reset prompt, training mission settlement, etc. This virtual platform provides a valuable tool for mastering UAV operations, which can improve efficiency and safety in actual applications.

Equipment Introduction

Pumping unit

Pumping unit inspection supports detection of imaging distance, focal length, and camera angle, and prompts correct camera specifications; supports detailed display of no less than 8 types of equipment including valves, oil ports, sucker rods, floating beams, brackets, balance blocks, motors, belts, etc.

Pumping unit overview

Pumping unit number plate

Pumping unit valve

Pump oil port

Sucker rod

Traveling beam

Bracket

Balance weight

Oil tank

Supports training mode and assessment mode; the training mode supports step list display, drone crash reset prompt, and training mission settlement. Supports photo imaging distance, focal length, and angle detection, and prompts correct photo specifications;

Tank number

Oil tank side A

Oil tank side B

Oil tank side C

Oil tank side D

Oil tank side E

Panorama of tank top

Inlet and outlet valves

Torch

Supports detection of imaging distance, focal length, and angle of photos, and prompts correct photography specifications; supports switching between infrared/visible light display modes; supports taking two photos (visible light photo, infrared photo) at the same time during inspection

Torch Point A

Thermal imaging inspection

Torch Point B

Torch Point C

Flare pipeline

Torch tower base

Imported valve

Oil and gas inspection video

When using drones for oil and gas inspections, repeated training using the srizfly drone simulator is the key to effectively improving work efficiency.

Product characteristics

♦Infrared patrol

Use an airborne infrared thermal imager to detect the surface temperature distribution of oil pumps, oil tanks, and flare equipment, obtain infrared image data, and find abnormal heating points in the equipment.

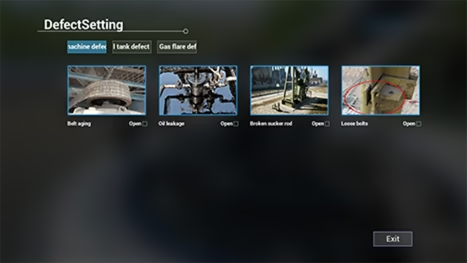

♦Dynamic Defect Library

The built-in dynamic defect library can flexibly set common defect types and supports typical defect settings, such as belt aging, wellhead leakage, bolt loosening, pump rod breakage, various deformations, cracks, corrosion and other defects.